Sealing the turret ring

By 1942, Germany had some experience in making Panzers capable of submerged travel in shallow water. External rubber seals were added to joints on the vehicles. But those seals were permanently fixed to the outside of the tank and could become damaged.

Very early in the Tiger's design process a decision was made to enable it for submerged travel [2, see 3.1.1] , as the vehicle's weight was too much for small bridges. Major welds of the hull plates were required to be watertight, and integral rubber seals were used in many unwelded joints.

The joint between turret and hull presented a problem. The two assemblies overlapped but did not touch, except via ball bearings. The gap between them could not be sealed with grease like that of an axle or torsion bar. It was decided to use an inflatable rubber tube [1, see page 10] .

The sealing tube

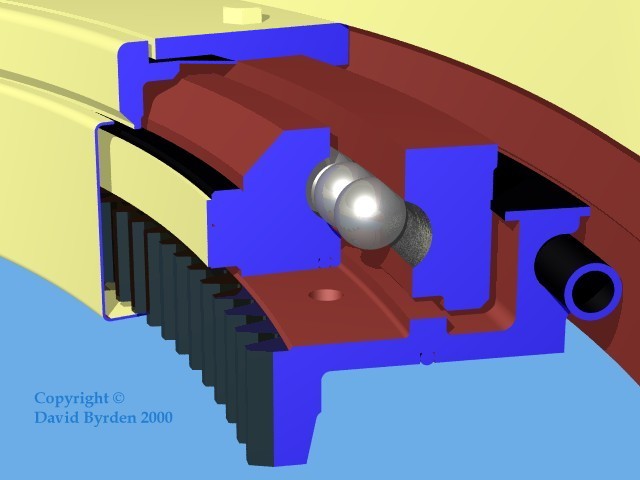

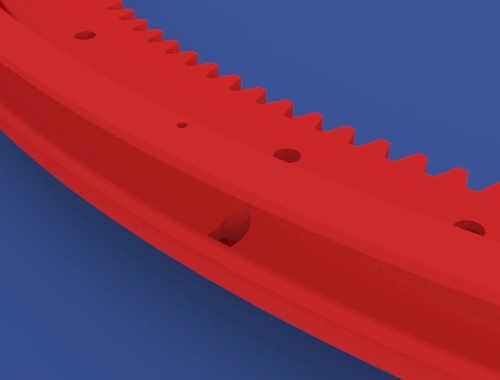

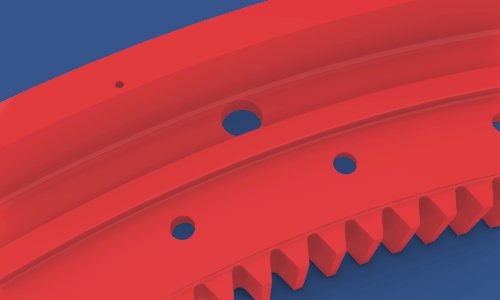

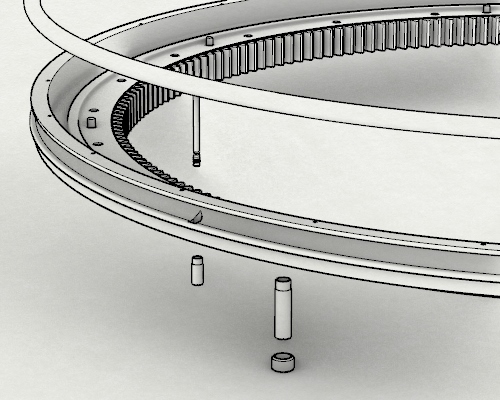

This is a cutaway model of the tank's original turret ring. The ball bearings sit inside the 2-part ball bearing race. That is placed upon the toothed base ring. That ring has a vertical outer flange with a channel, and a rubber tube is placed in that channel.

The toothed ring is fixed to the hull, while the turret's armoured wall (at the right of the image) moves around it. By inflating the tube, you force it to press against the flange and the wall, sealing that gap. The turret was supposed to be locked beforehand.

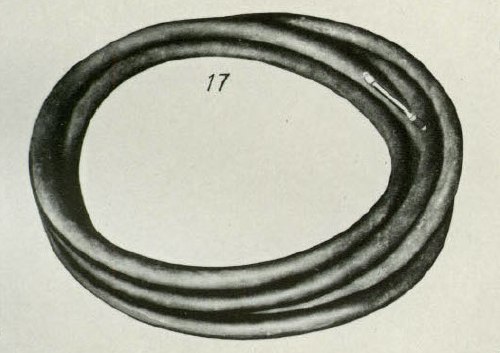

This photo of the tube is from a parts manifest. It had a nominal diameter of 30mm and a length of about 678cm. It weighed 1.5kg. [4, see Tafel 83]

It had a single inflator valve [1, see plate 8] .

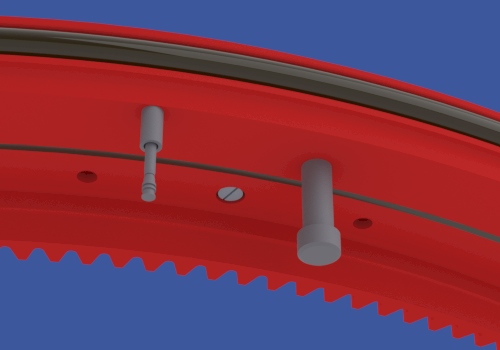

While inserting the tube into the channel on the toothed ring, you would push the inflator valve into this small hole, and it would emerge below the ring.

The drain

It was anticipated that the rubber sealing tube might fail or deflate, allowing water into the ball bearing race. So, at the inner surface of the turret ring, there was a secondary seal as a backup. But water would then remain trapped in a U-shaped channel in the toothed ring, causing rust. Therefore, this channel had a drain. The largest hole in this model is the drain hole.

The drain and the inflator valve both had screw caps and rigid protective sleeves [1, see plate 8] . They were positioned together in the front left quadrant of the toothed ring. This model shows both of them. The sealing tube is visible also. When the turret was installed, both items protruded into the crew compartment, beside the turret lock.

Parts and accessories

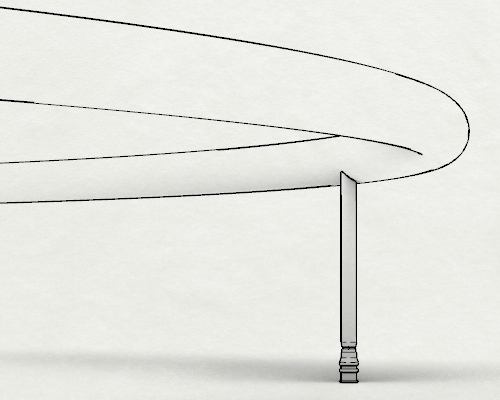

This "exploded" model shows the parts of the sealing tube and drain.

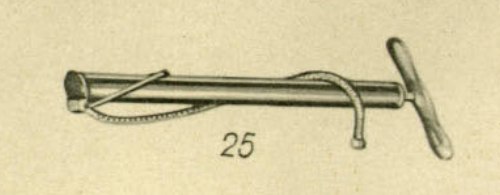

This hand pump, specifically for inflating the tube, was issued to one in every five Tigers. [4, see Tafel 100]

A "stick air pressure gauge in a sleeve" came along with the pump. There was also a "socket wrench with universal joint" which is not pictured in the manifest. I don't know its purpose.

The end

In September 1943, the Tiger's submersion ability was deleted [2, see 3.4.1.5] . The inflatable sealing ring and the drain were no longer built into Tigers.

[2] Germany's Tiger Tanks, volume 1 : DW to Tiger 1

[3] Survey of Tiger 250122, at Bovington museum, by David Byrden

[4] Kraftfahrgerät teil 3, Fahrgestell und Turm Panzerkampfwagen "Tiger", heft 60