About this detail of the Tiger

The Tiger's original HL 210 engine had an inertial starter on its forward right corner. It was driven via an axle and a chain from a gear wheel at the rear of the engine.

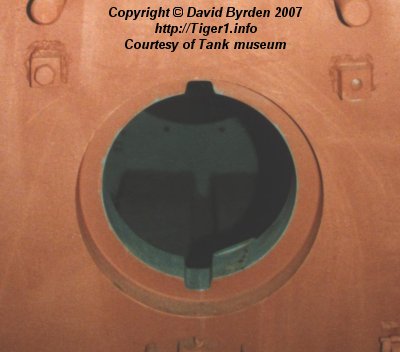

To reach this gear wheel from outside the tank you would remove a circular panel at the bottom center of the rear plate, as shown above [2] .

This revealed a hole of 200mm internal diameter [1] . It had notches above and below.

To ensure the alignment of the starter handle, an adapter was then fitted into the hole. The sleeve for the starter handle could be screwed into a collar in the center of this device. This is the original design of the adapter.

The adapter was made of a pressed metal dish with a metal ring welded to the underside. The ring, of 250mm diameter, slotted into the hole in the hull wall. This photo of the underside shows the welded ring. At the top and bottom there are small teeth that fit into the notches, ensuring that the device sits horizontally.

The adapter was stored on two tubes welded to the rear wall. This is one tube. Each tube had internal guide sleeves.

Two long rods on the back of the adapter slotted into the tubes. These rods contained T-shaped latches that could be turned to lock the adapter in place. This example (in Bovington museum) is missing one of the latches [1] .

The latches were turned by hexagonal nuts on the face of the device. They can be seen here, on the Bovington vehicle. This is the second type of adapter, with a tool holder and a small hole added.

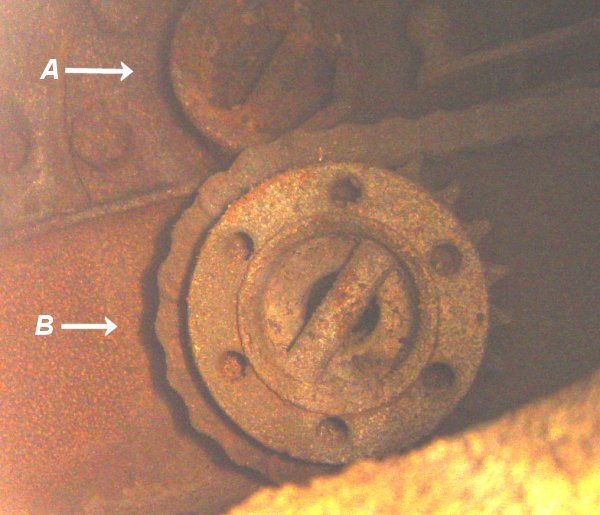

In May 1943, the Tiger's engine was changed to the HL 230 [4] . The new engine was dimensionally the same, but the gear wheel for its starter was moved slightly. This photo [5] , taken through the starter port of the Tiger in Saumur museum, shows the new arrangement. The end of the crankshaft [A] is where the HL 210 gear wheel was mounted. But now the gear wheel and drive chain is at [B].

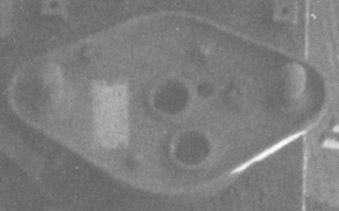

Therefore a second collar was added to the adapter, with the original collar retained for back-compatibility [4] . This detail from a wartime photo shows both collars (and a new tool holder).

This profile shows the adapter installed in the 80mm rear armour of the Tiger. The back plate was slanted 9 degrees from vertical, so the adapter was carefully shaped to compensate.

The adapter was also used to fit starter motors to the Tiger. These standardised starters were held in place by two arms that slotted onto the two large poles on the adapter. As you can see here, the poles sat horizontally.

In February 1944 the adapter was redesigned to make its manufacture easier. This almost coincided with the introduction of steel wheels, so this fourth variation of the adapter is found on 'Late' Tigers.

The ring was no longer welded to the back of the pressed plate; instead, it was attached by two large bolts [4, see 3.4.1.4] . They can be seen here to the left and right of the central collar. Flat pieces of metal were crudely welded inside the ring so that it could carry these bolts. The locking rods were also fixed to the ring, and they are now reached through holes in the front plate [5] .

This adapter (on a Sturmtiger at Munster museum) has been bent, causing the ring to separate from the front plate. You can see where small metal plates have been welded inside the ring.

[1] Survey of Tiger 250122, at Bovington museum, by David Byrden

[2] Survey of Sturmtiger at Panzermuseum Munster, by Rob Veenendaal

[3] Survey of Tiger 250122, at Bovington, by Vince Abbott

[4] DW to Tiger 1

[5] Survey of Tiger 251114, at Panzermuseum Munster, by Rob Veenendaal