About this detail of the Tiger

The Tiger had numerous lubrication points. The lubricating agent may have been grease, I have not researched it yet. Most of the lube points were individual taps, but for the swing-arm bearings 40 taps were grouped in 4 panels under the fighting compartment floor.

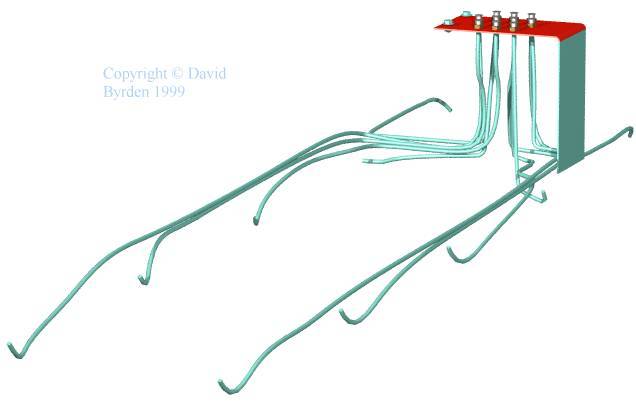

The panels were painted red (the same colour was used for the individual taps at other lubrication points). Ten taps in the top of each panel led to ten tubes underneath, which ran directly to the individual bearings in the hull. This 3D model shows the front right-side panel and tubes.

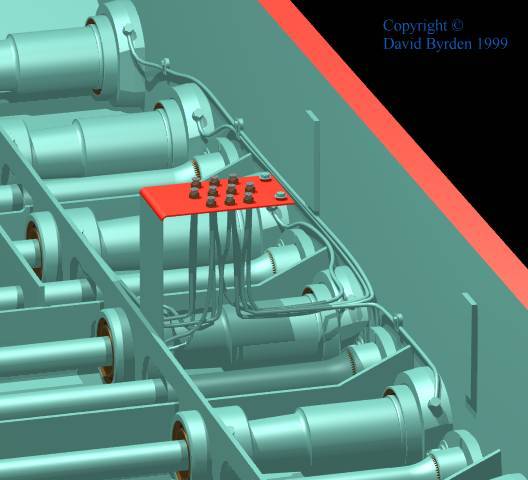

All four of these red panels were bolted at their outer end to the floor support beams which I have omitted from the model below. The forward two panels extended directly down to the floor stiffeners, as you can see in this model:

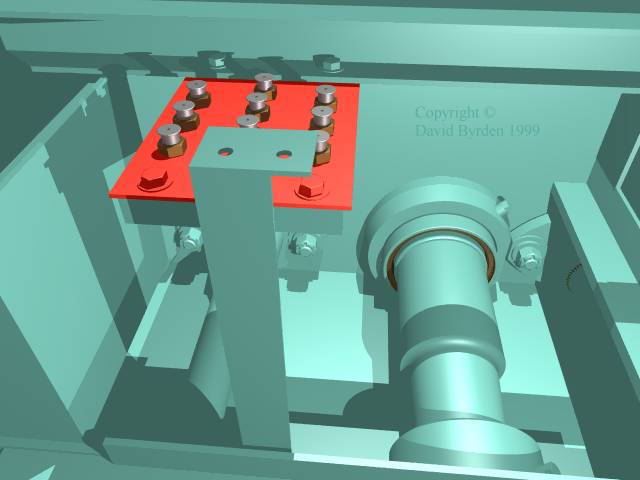

The rear two panels were bolted to pillars that also held up part of the floor. The model below shows the right-side rear panel; it lacks the tubes, which I have not yet built. Although I have modelled these plates nice and clean, they were black with spilt lubrication when a tank had been used for some time.

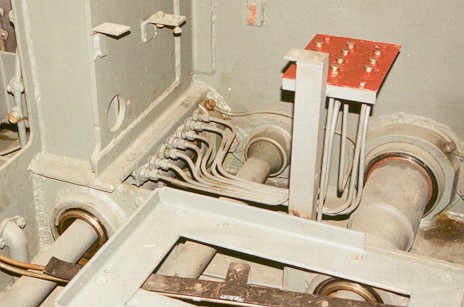

To see the exact positions of these four plates, refer to the hull layout. This next photo shows the lubricating pipes in place under the left-hand panel.

The book "Tiger und seine abarten" by Walter Spielberger has two curious photos showing a "high pressure central lubrication system" installed in the 3rd prototype of the vehicle. This system comprised a large canister behind the driver's position which supplied pressurised lubricating oil to all 40 of these taps through individual pipes. It seems that the experiment was unsuccessful and so Tiger crewmen were obliged to top up all 40 by hand as part of maintenance duties.

[1] Survey of Tiger 250122, at Bovington museum, by David Byrden