About this detail of the Tiger

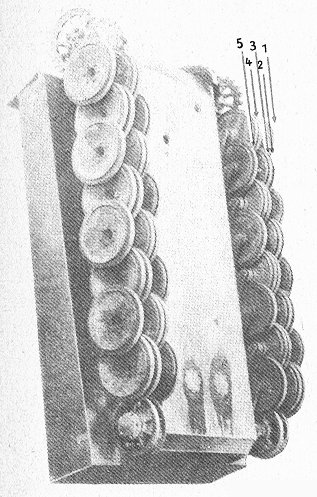

The original design of the Tiger specified 40 road wheels arranged in 5 rows per side. This next photo from the Tigerfibel shows the layout.

Each wheel carried one or two external rubber tyres. The wheels (800mm diameter) were made of metal discs with forged rims and had welded construction. The tyres were attached by bolted flanges.

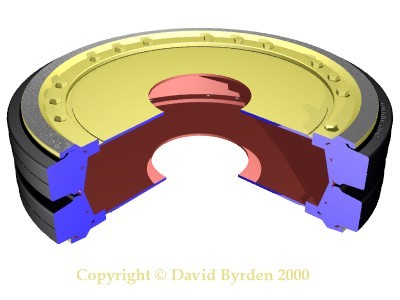

Only 8 of the 40 wheels carried two tyres; they ran between the guide teeth of the track. Here, a CAD model shows the general structure of these wide wheels.

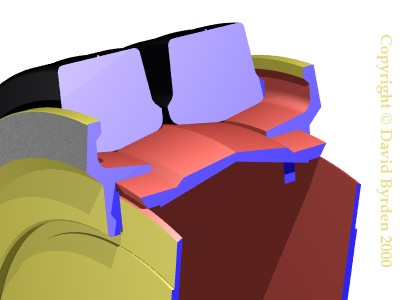

The other wheels all carried a single tyre. Their body comprised a flat metal disc welded to a dished disc. At thick solid bearing ring was welded at the center, carrying 6 unthreaded holes for the fixing bolts. This diagram describes any of the wheels on the 3 outermost rows.

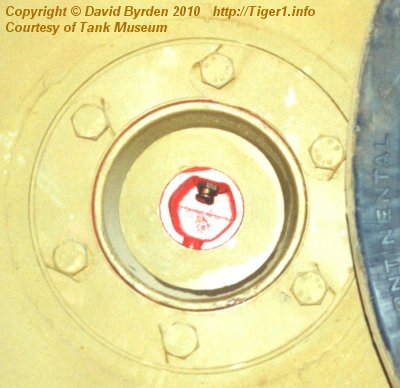

This photo shows the solid bearing ring at the back of the wheel. I don't know the purpose of the additional large holes drilled in the bearing ring.

The innermost wheel, adjacent to the hull, had a larger central hole but was otherwise identical.

Between the central bolt holes, there were 4 additional small holes. They don't seem to serve any purpose and may be a byproduct of the manufacturing tools.

They were usually placed centrally between bolt holes, but in some cases were not. Both of these layouts have been seen.

When the wheels were bolted in place, a circular ring of sheel metal would cover the smaller holes as you can see here. But wartime photos suggest that the crews would often discard or lose these rings during maintenance, exposing the holes. The locking tabs for the bolts were usually not mislaid.

It appears that the two designs of locking tabs were used, with the second one appearing in April 1943.