About this detail of the Tiger

As first designed, the Tiger provided its driver with a direct-vision visor and an episcope; but the latter was deleted in February 1943. There was a periscope in the driver's hatch, but it faced to the side and could not rotate.

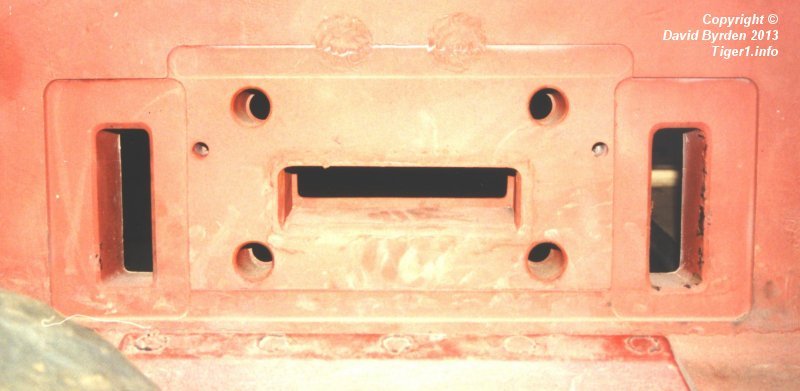

This photo (of the Vimoutiers Tiger) shows the external layout of the visor. The driver peered through a slit whose size he could adjust by moving two armour shields. The upper and lower shields were geared to move simultaneously, preserving the center of the slit. At left and right there were fixed steel covers. A guard bar was bolted into the glacis plate to protect the bottom joint.

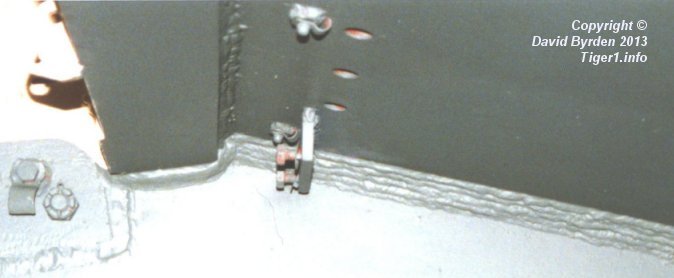

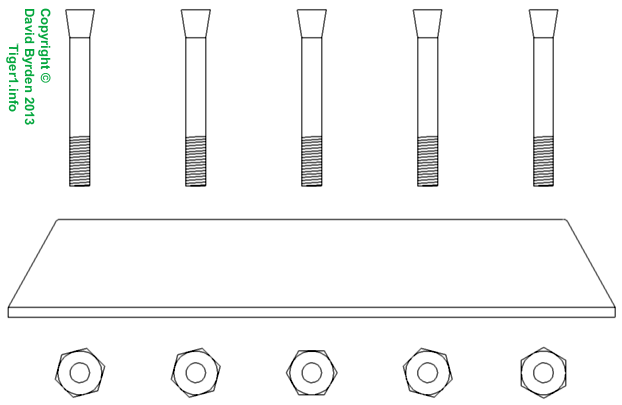

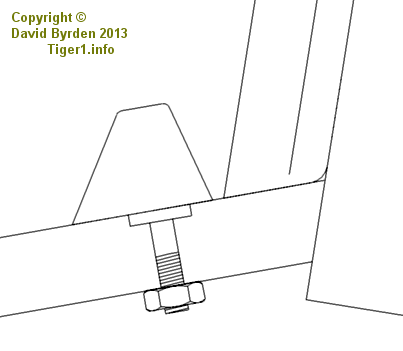

Looking from above, we can see that the side armour blocks provide machined channels to guide the movable shields. The bar on the glacis plate is keyed into a channel as well as being bolted. Its bolts have tapered flat heads, minimising the chance of damage from impacts.

With the visor components removed, this is the external appearance of the port (on the Bovington vehicle during restoration). In this particular hull the armour was drilled with two holes for the episcope, above the visor, but they were plugged when installation of the device was cancelled. A standard German vision block was located behind the central opening. I don't know the purpose of the two smallest holes; they were blocked by the upper shield in all positions.

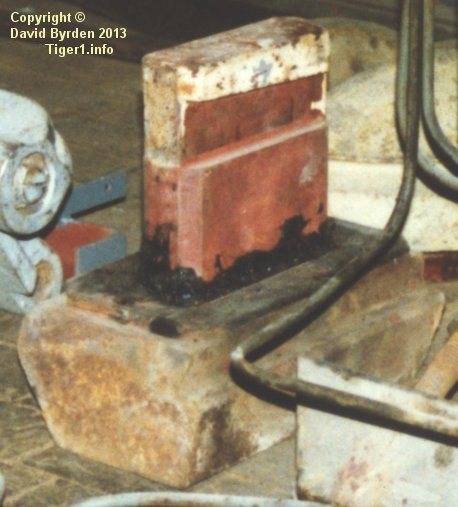

This is one of the side covers (with its original primer and ivory paint). The long tab extends through a hole and into the tank. The cover is also keyed into a recess in the armour, 10mm deep.

Inside the tank, the end of the tab was locked solidly in place by hammering a U-shaped piece of metal into it. The U was longer than the tab, presumably so that something could be inserted to provide leverage for hammering it out again.

The movable shields were raised and lowered by cams, two each, on axles that were turned from inside the tank. I have no images of the cams. At the top and bottom, long channels were machined into the front plate, 5mm deep and 30mm wide, along the full width of the shields. This ensured that the upper and lower edges of the moving shields were not in contact with the front plate; if they had been, tiny steel splinters from impacts could have become caught in them and prevented their motion.

All of the components described above were solid steel blocks. There was no external mechanism except for the rotating cams, which fit into holes on the back of the shields. Waterproof sealing apparently consisted of grease on the backs of the side armour blocks, seals in the bearings of the cams, and seals on and around the vision block inside the wall.

This view inside the Bovington tank (after repainting) shows some of the holes for the bolts of the guard bar.

These are diagrams of the guard bar.

[1] Survey of Tiger 250122, at Bovington museum, by David Byrden