Tank components can be made in several ways, e.g. casting, stamping, and rolling. Each process results in a different surface texture. Casting tends to make rough, imprecise shapes; when that is a problem, then the cast part gets completed by machining, which makes for a very smooth surface.

A high quality model kit will attempt to depict the textures of the various parts. This Tiger kit from Border appears, at first glance, to be in that category because it has both rough and smooth parts. But when we compare Border's parts to the real tank, we find that Border often choose the wrong texture - usually they make a smooth thing rough. You can make your model more realistic by removing Border's textures.

Specific parts

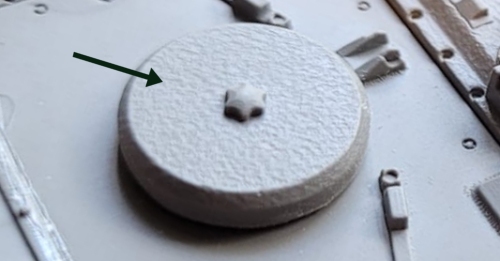

This is the air intake cover on the engine hatch. Border have given it a rough finish; compare it to the underlying hatch.

But the real cover is made of smooth plates carefully welded.

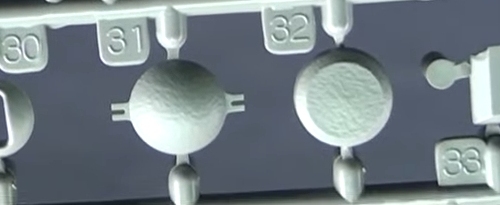

Both of these parts have the wrong texture. On the left is the optional cover for the hull MG. The real one was made of pressed sheet metal and was very smooth. Part 32, to the right of the image, is the ventilator cover.

This is the real vent cover on Tiger "131". It is machined to a very smooth finish.

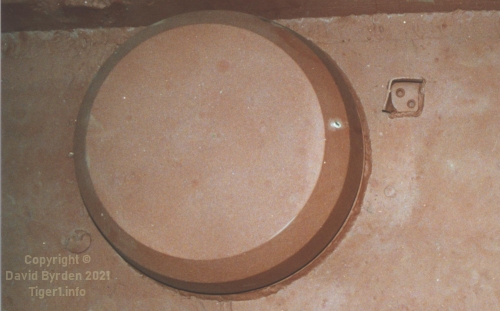

This detail of Border's kit is the hub of the sprocket wheel, the "round" version. Border gave it a very rough finish indeed.

But the real hub was machined to be relatively smooth. In this photo, the light catches the fine grooves made by the machine tool.

These are the main fans. The real ones have very smooth hubs. Border, once again, give their hubs an inappropriate rough texture.