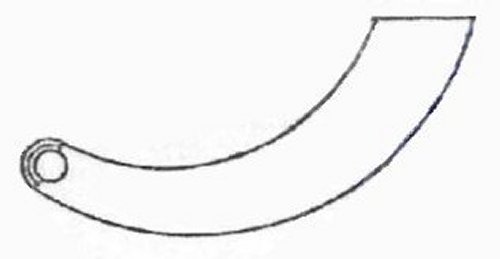

The support arm

The loader's hatch could be fully opened to lie on the turret roof, or could be locked open while standing exactly vertical (this does not apply to "Late" Tigers which had a thicker roof).

Locking was achieved by a plunger, fixed under the roof, that engaged with an arm attached to the hatch. This German diagram shows the shape of the arm. The plunger would enter the hole at the end of the arm.

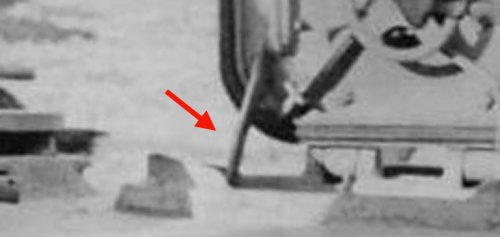

The hole was reinforced with a small welded strip of metal, indicated here and drawn on the diagram.

The arm was made of thin metal, and it was deliberately bent to accomodate the shape of the hatch. This hatch is locked open, we are looking at it from behind, and it's obvious that the arm is not straight.

The arm in this kit isn't a good representation of the real one. It resembles the arm on Tiger "131" of Bovington Museum. That tank lost its original arm and it was not accurately restored.

The kit's arm has a plunger device instead of a hole, it's straight, and it's thicker than it should be.

Two kinds of hatch

Two manufacturers supplied Tiger 1 turrets, and they had different ways of making a loader's hatch. One used forging, and the other used welding.

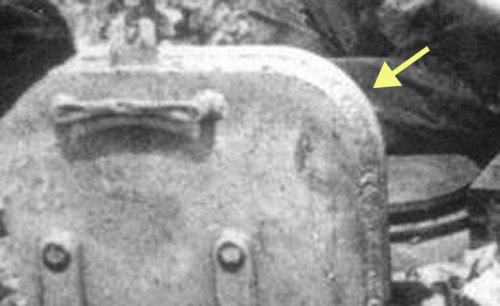

This is a welded hatch. It comprises a flat steel plate welded on top of a hollow frame. There is visible weld (arrowed) all around the edge.

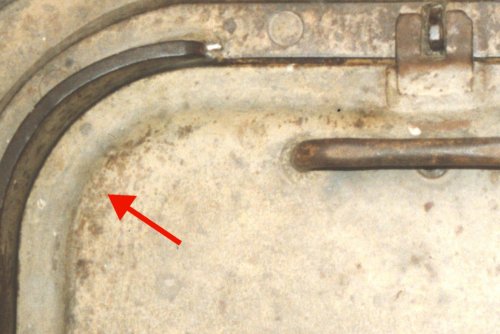

This is a forged hatch. It is a single piece of metal pressed into shape.

Both kinds of hatch were installed on Tigers almost at random. You generally cannot say which type was on a specific Tiger unless you have a good photo.